Maple Leaf Foods faced the challenge of consolidating three existing facilities into one, driven by the need to relocate from Toronto’s expensive and densely developed area. This initiative also aimed to increase their production capacity to meet growing demand.

Inspired by European poultry facilities, the primary objective was to create a cutting-edge facility In London, Ontario, capable of transitioning from a water-chilled process to an air-chilled process. By adopting air-chilling methods, Maple Leaf Foods ensures superior product quality, avoiding water-weighted containers commonly seen in stores.

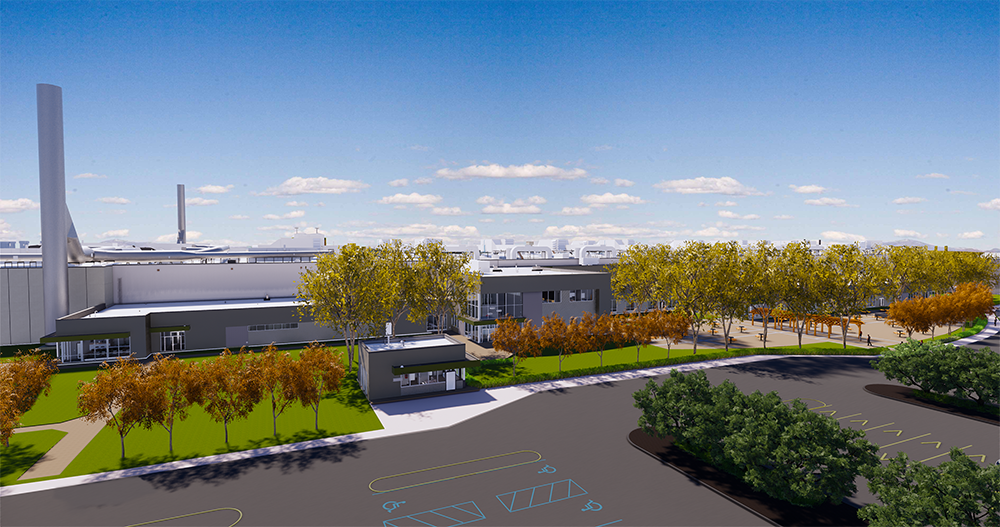

In Partnership with Hixson Architecture, Engineering, and Interiors based in Cincinnati, Ohio, our architects, and engineers were crucial to the project’s success. We provided essential services such as design review, permitting, and site plan approval. The facility is surrounded by sensitive land and required close collaboration between the consulting team and the Authority Having Jurisdiction to ensure that the development resulted in a net positive benefit to the ecosystem.

Due to COVID-19 restrictions, we acted agilely, taking on additional responsibilities such as conducting field reviews when Hixson could not cross the border. Despite the challenges posed by the pandemic, we successfully provided leadership and support during the value engineering stage, streamlining operations, and coordinating with contractors and subcontractors to overcome supply and material delivery issues. Our dedicated efforts allowed Maple Leaf Foods to focus instead on its core tasks, confident we were handling project requirements.

The new plant blends innovation and efficiency and meets the highest standards. It prioritizes employee well-being, fosters economic growth, and implements responsible environmental practices. It is a significant milestone for the Canadian food industry and sets a new standard for excellence.